Pre-post today. I’m going to try to drill the radial screw holes today.

I don’t have the proper tools to do this (a large indexing head). On top of that, if I mess up, I’ll ruin my back plate. I’ve got an idea for how to do it though, and I’m going to go for it today.

I can’t fit this pipe on the lathe at all, so even scribing an accurate circumference line will be difficult.

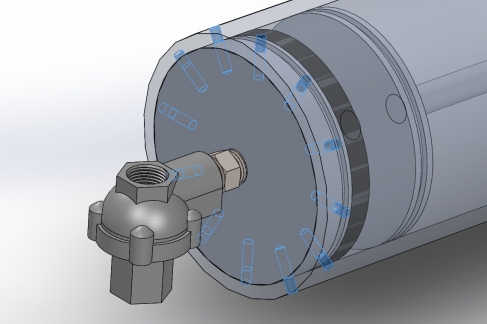

My plan is to polish the OD, and carefully measure the circumference. I’ll then print out a template to wrap around it. If I pull the paper flat and line up the ends, it should sit fairly square on the pipe. I’ll punch through it to mark the holes.

I’ll also use the edge of the paper to mark a circumfrence line on the back edge of the pipe. That way I can square it up with a file.

I’ll fix the back plate on somehow and drill it at the same time. That way even if the holes aren’t perfect they’ll still line up. If I really nail it, the end cap might even fit in any orientation. ..We’ll see how that goes. Wish me luck.